Supporting production of pharmaceuticals and functional materials with purification technology

YMC can support our customers’ production of pharmaceuticals and/or functional materials with our purification technologies, which we have accumulated over many years. Please feel free to contact us if chromatographic purification will be needed during the manufacturing of biopharmaceuticals, chiral compounds, impurities etc.

API Purification Plant for pharmaceuticals, which is compliant with GMP requirements, has also been established, and we have just started a full-scale contract purification service for high-value-added substances, including biopharmaceuticals. We can optimize methods, depending on the objective and required purity, and perform preparative purification using preparative LC systems and packing materials, developed and produced in-house.

In addition to ensuring qualification of target substances according to your request, we will also propose an efficient separation method that may result in a cost reduction, based on our past achievements and know-how.

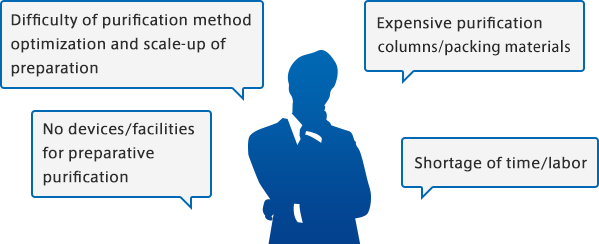

Separation and purification using chromatography has high technology, time, and cost requirements. At YMC, we provide purification service using our accumulated experience, know-how, and excellent equipment.

Separation / purification chromatography

Are you having trouble?

Use of a service provided by YMC

Supply of high-purity compound

Quick service

High credibility

Low cost

| System | Column inner diameter | Scale | Target substances |

|---|---|---|---|

| Preparative HPLC device | 10-1000 mmI.D. (Packed columns / Axial compression columns) |

mg to ton |

|

| LPLC device (Bio-LC device) |

10-1000 mmI.D. (Glass / Acrylic columns) |

mg to ton |

|

| Continuous Chromatography System | 4.6-50 mmI.D. (Packed columns / Glass columns) |

to g |

|

Raw materials

(Peptides, oligonucleotides, etc)

Ion exchange chromatography

Ion exchange chromatography

Reversed-phase chromatography

Concentration and drying

Purified material

(~500 kg/year)

| Purification request |

|

|---|

| Report for preliminary test results |

|

|---|

| Submission of quotation |

|---|

| Actual purification |

|

|---|

| Delivery of the purified material and reports |

|---|

Through YMC worldwide network, we secure our global supply chain and customer service. Our purification service will be soon available not only in Japan but also in Europe, the U.S. and India. We are also planning to increase our offices mainly in countries and regions where the pharmaceutical business is expected to grow.