Overview of optimization methods for isolation/purification

An overview of the methods for selecting optimum conditions for isolation/purification and conducting efficient isolation, as well as key factors are given below.

Selection of a preparative column

1) Selecting the separation mode of chromatography

(investigation of separation conditions using various analytical columns)

When more than one mode is available for the separation of samples, the following key factors should be considered for the selection of an appropriate separation mode.

- Resolution: Selectivity of the packing material for the compound of interest

- Load: Capacity of the packing material

- Speed: Isolation time

2) Column size

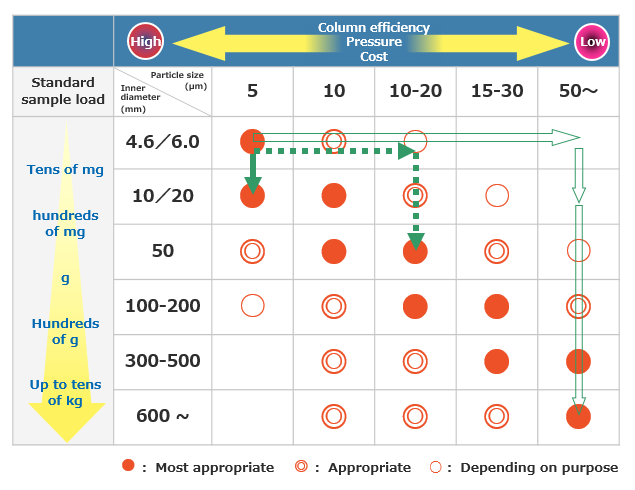

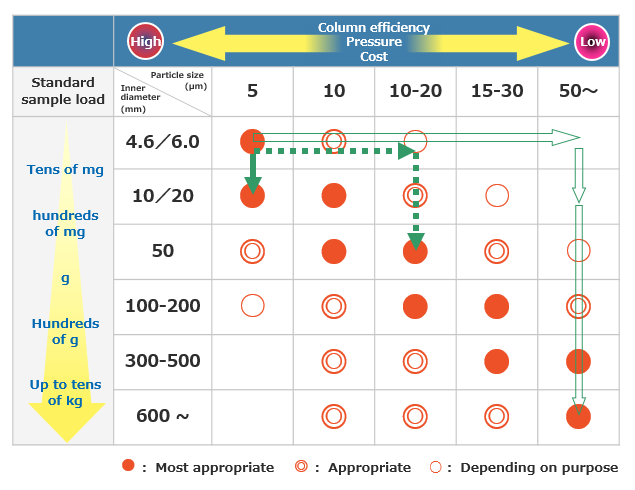

The table provides a rough guide for the selection of column inner diameters and packing material particle sizes.

- Column inner diameter

Sample load is proportional to the column cross-sectional area.

It is necessary to select a column inner diameter suitable for the sample load.

- Packing material particle size

Smaller particle sizes can provide higher column efficiencies, but have higher prices. More over, owing to the higher pressures applied to columns with smaller particle sizes, the equipment needs to be resistant to pressure.

When the distance between the target component and the nearest peaks is very close, higher resolution is required and packing materials with small particle sizes are effective. In contrast, column efficiency is lower for larger particle sizes, but the price and column pressure are lower.

- Column length

Better separability can be obtained with longer column lengths and higher sample loads can be tolerable, but the longer the column, the higher the column pressure becomes.

General guidane for selection of preparative columns

The analytical conditions established using the analytical column are scaled up to the intended preparative scale in the direction shown by the arrow

Optimization of separation conditions

3) Investigation of preparative separation conditions with packing materials of the selected size.

Optimize preparative separation conditions with analytical columns.

- Optimization of elution conditions

Unlike analysis, the top priority of preparative separation is to obtain the target component efficiently with high purity and recovery. A key to performing efficient preparative separation is to set the elution conditions by considering which components should and should not be separated.

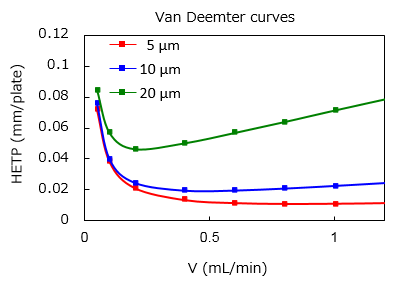

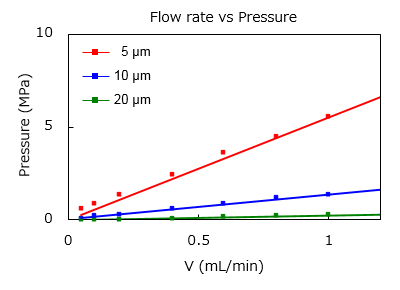

Packing materials with larger particle sizes than those for analytical purposes compromise the column efficiency, losing required separation. In such cases, improve the separation by adjusting the elution conditions and/or reducing the linear flow rate. If the separation is not improved, change the column length and/or the particle size.

Relationship between flow rate and column efficiency/pressuer

| Column |

YMC-Triart C18-S (120 Å)

150 X 4.6 mmI.D. |

| Eluent |

acetonitrile/water (60 / 40) |

| Flow rate |

1.0 mL/min |

| Temperature |

25℃ |

| Detection |

UV at 254 nm |

| Injection |

5 μL |

| Sample |

n-butyl benzoate |

- Investigate the load

Increase the load stepwise and work out the maximum load to obtain the desired purity. Calculate the load based on this maximum load if scaling up to a preparative column.

- Inspection on a preparative system

Carry out an inspection to verify that the flow rate and the column pressure to be applied for the actual preparative separation are in compliance with the system performance. In order to obtain the same separation as the column for investigation, the linear flow rate of the preparative column should be the same as that of the column for investigation. The same linear flow rate is obtained by setting the flow rate of the preparative column to be the same as the cross-sectional ratio of the flow rate of the column for investigation. If the linear flow rate is the same, the pressure of the preparative column will be the same as that of the column for investigation. If the column pressure exceeds the pressure capacity of the system, the flow rate, column length, etc. need to be changed.

The piping system should be changed to comply with the applied flow rate.

Relationship between column inner diameter and flow rate/sample load

Column inner diameter

(mmI.D.) |

4.6 |

10 |

20 |

50 |

100 |

200 |

500 |

1000 |

| Cross-sectional area |

1.0 |

4.7 |

19 |

118 |

473 |

1,890 |

11,800 |

47,300 |

Flow rate

(mL/min) |

0.5 |

2.4 |

9.5 |

60 |

235 |

950 |

6,000

(6 L) |

24,000

(24 L) |

| 1.0 |

4.7 |

19 |

120 |

470 |

1,900 |

12,000

(12 L) |

47,000

(47 L) |

Sample loading

(mg) |

5 |

25 |

100 |

600 |

2,500 |

10,000 |

60,000

(60 g) |

240,000

(240 g) |

When the same packing material and column length are used, the preparative flow rate and sample load are proportional to the column cross-sectional area. Additionally, the resolution and column pressure experienced on the preparative column are approximately the same as those for the analytical-scale separation.

Flow rate equation

F’=F×(Dc’/Dc)2 F:Analytical column flow rate (mL/min)

F’:Preparative column flow rate (mL/min)

Dc : Analytical column inner diameter (mm)

Dc’: Preparative column inner diameter (mm)

*Use the same equation to calculate the sample load.

4) Perform preparative separation

Carry out the preparative separation and evaluate the yield and purity.