Eicosapentaenoic acid (EPA), an unsaturated fatty acid, is effective for reducing neutral fat levels, improving blood circulation, etc. It needs to be taken from external sources because the human body can’t produce it. Many products are available on the market as EPA supplements and as pharmaceutical products in the form of eicosapentaenoic acid ethyl ester (EPA-EE). Following is an example for EPA-EE preparative separation.

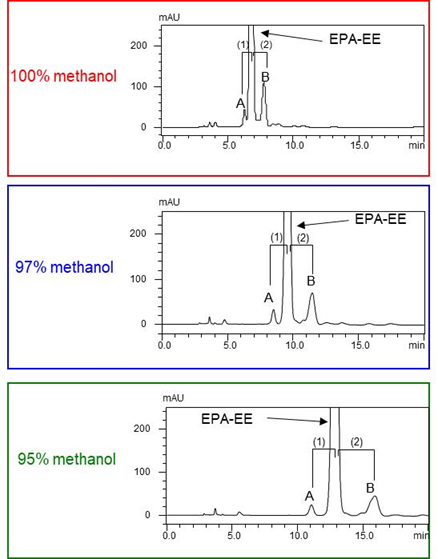

First, separations between the EPA-EE peak and the nearest peaks were studied on the analytical scale. When comparing separations with different methanol (organic solvent) ratios in the mobile phase, better separation can be obtained with lower methanol content although the separation time became longer.

eicosapentaenoic acid ethyl ester (EPA-EE)

| Mobile Phase | tR (min) (EPA-EE) |

Rs (1) (A, EPA-EE) |

Rs (2) (EPA-EE, B) |

|---|---|---|---|

| 100% methanol | 6.76 | 1.33 | 2.18 |

| 97% methanol | 9.56 | 1.99 | 2.78 |

| 95% methanol | 12.81 | 2.56 | 3.24 |

| Column | YMC-Omega (10 µm), 250 X 4.6 mmI.D. |

|---|---|

| Flow rate | 1.0 mL/min |

| Temperature | 25°C |

| Detection | UV at 210 nm |

| Sample | 4 mg/mL of 70% EPA-EE |

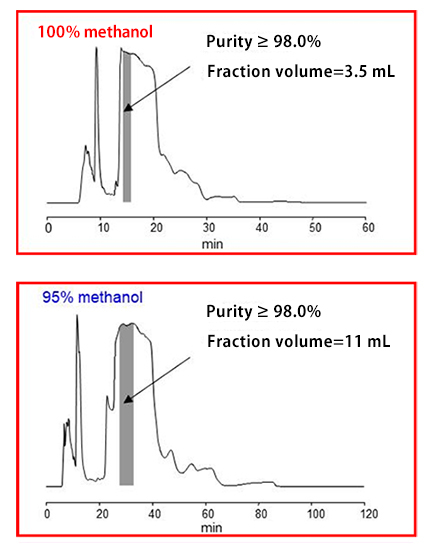

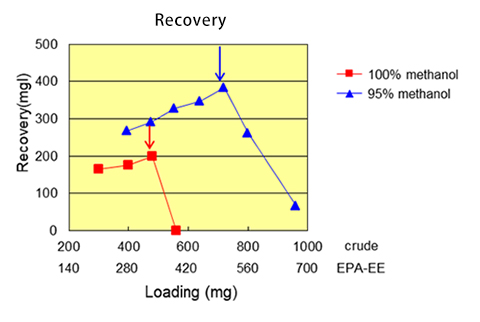

Preparative separation efficiency using different methanol ratios in the mobile phase was compared using a semi-preparative column with a 10 mm inner diameter. With 100% methanol as the mobile phase, loading, a recovery rate, and a recovery amount per cycle were lower, but a recovery rate per unit time was equal to or greater than that with 95% methanol as the mobile phase because the cycle time was reduced by half. In addition, the volume of the fraction with 100% methanol was 1/3 of that with a 95% methanol condition. The time needed for post-column treatment was also reduced as the volume of fractions was reduced. In this case, because productivity per unit time is prioritized over recovery rate, 100% methanol mobile phase is chosen for the large-scale preparative separation.

| Column | YMC-Omega (10 µm) , 250 X 10 mmI.D. |

|---|---|

| Flow rate | 2.0 mL/min |

| Temperature | 25°C |

| Detection | UV at 210 nm |

| Sample | 70% EPA-EE |

| 100% methanol | 95% methanol | |

|---|---|---|

| Loading (EPA-EE loading) |

480 mg (336 mg) |

730 mg (511 mg) |

| Recovery | 200 mg | 380 mg |

| Cycle time/run | 45 min | 90 min |

| Fraction volume | 3.5 mL | 11 mL |

| Cycle/day | 32 times | 16 times |

| Recovery/day | 6.4 g | 6.1 g |

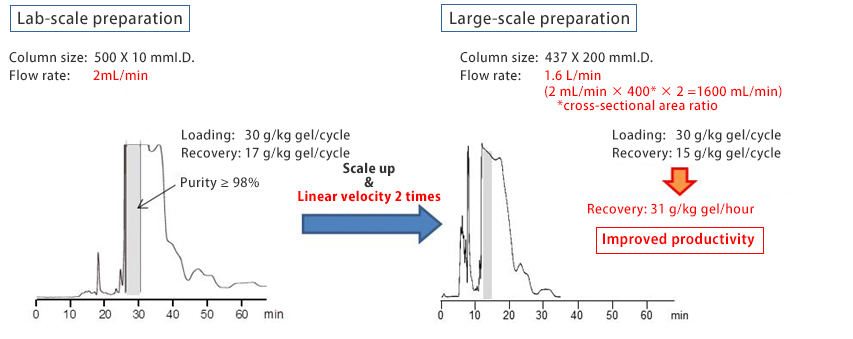

Optimized conditions from the semi-preparative column with a 10 mm inner diameter were scaled up to the production using dynamic axial compression column with a 200 mm inner diameter. Normally, the flow rate is increased by the cross-sectional area ratio (400 times) to obtain the same resolution. In this case, however, the flow rate (Linear velocity) was doubled to improve the productivity. 1.8 times more productivity per unit time was achieved because the time for each run was reduced by half but with a slightly reduced recovery amount.

| Column | YMC-Omega (10 µm) |

|---|---|

| Eluent | methanol |

| Temperature | ambient |

| Detection | UV at 210 nm |

| Sample | 70% EPA-EE |